Product Categories

All Products

-

Bearing Grade PEEK Tube Chemical Resistance

PEEK tube can be used at high temperature continuously almost 260 cent degrees, and without losing its physical properties and chemical properties. PEEK shows high stiffness and hardness, and an unique high tensile strength and fatigue strength. PEEK provides good dielectric properties when the temperature ups to +260 cent degrees

-

Industrial Engineering Plastic Products

Nylon PA rod is an excellent product and is the first engineering resin. It has been used in applications ranging from electronic, marine, and automotive industries to fibers used to make carpet. Nylon has outstanding wear resistance and low frictional properties. It has very good temperature, chemical, and impact properties. However, nylon's one weakness is a propensity to absorb moisture and thus have poor dimensional stability.

-

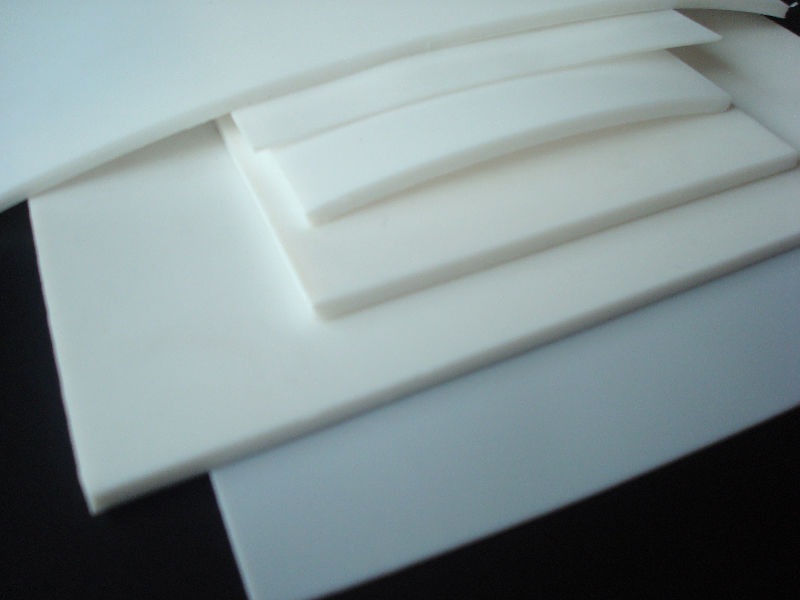

Customized Industrial Engineering Plastic Products Nylon PA Sheet For Fan Blades

Nylon PA sheet is produced by virgin nylon PA6, PA66 with injection molding, extrusion and blow molding, etc. Nylon sheet/PA sheet is recognized as the most widely used and known engineering plastic in the current market. 6 Nylon Sheet has the best performance, very tough, even at low temperatures, and high hardness in the surface, toughness, mechanical lower shock, and abrasion resistance. Combined with these characteristics and good insulation, and chemical properties, it has become common-level materials.

-

Flexible Industrial Engineering Plastics

Nylon PA tube is a strong, stiff engineering plastic with outstanding bearing and wears properties. Nylon is frequently used to replace metal bearings and bushings often eliminating the need for external lubrication. PA tube is recognized as the most widely used and known engineering plastic on the market and for good reason. Nylon tube has Good wear ability, smooth surface, low resistance, anti-rustiness and anti-scaling, and so on.

-

High Stiffness Industrial Engineering Plastics

PC rod is a kind of transparent thermoplastic resin which has good strength and stiffness and outstanding impact resistance. Polycarbonate Rods are an excellent product for safety and security applications. They are light-weight and has 250 x the impact strength of glass. High mechanical impact strength, even at low temperatures. Stiffness retention over a wide range of temperatures with good dimensional stability.

-

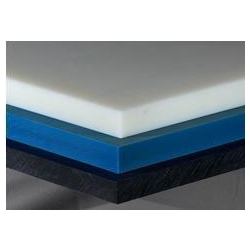

Industrial Engineering UHMWPE Sheet

UHMW-PE sheet will not encourage growth of bacteria or fungus, is self-lubricating, and it meets FDA requirements for direct food contact. UHMW-PE sheet resembles other polyethylenes in superficial characteristics such as texture, color, stiffness, weight and general apperance

-

Engineering UHMWPE Plastic Sheet Industrial Corrosion Resistance

UHMW-PE sheet will not encourage growth of bacteria or fungus, is self-lubricating, and it meets FDA requirements for direct food contact. UHMW-PE sheet resembles other polyethylenes in superficial characteristics such as texture, color, stiffness, weight and general apperance

-

Anti-uv Polyethylene UHMWPE Sheet Fabric Cutting Board Recycled

UHMW-PE sheet will not encourage growth of bacteria or fungus, is self-lubricating, and it meets FDA requirements for direct food contact. UHMW-PE sheet resembles other polyethylenes in superficial characteristics such as texture, color, stiffness, weight and general apperance

-

Food Industry UHMWPE Bar 150mm Industrial Engineering Non-Toxic

UHMW-PE Rod is a super engineering plastic that is probably not as well known as some other engineering plastics but can out perform its relatives in a number of important areas.UHMW-PE Rod has a few very important properties and the first would be its incredible resistance to abrasion. UHMWPE can out perform almost any engineering plastic for abrasion resistance and UHMWPE is probably one of the best materials for lining chutes and hoppers for products such as sand, concrete or any other highly abrasive moving product. Another important property of UHMWPE Rod is it's incredibly low co-efficient of friction, this is one of the lowest of all engineering plastics and will produce components with a very high life span with very low drag. UHMWPE Rod is resistant to many dilute acids, solvents and cleaning agents

-

Carbon Gland packing Solvent Resistance High Strength Self lubrication

High carbon packing made of high carbon fiber and graphite filled into material, adding lubricant. High carbonized fiber packing is manufactured by heating polyacrylonitrile fiber into carbonized fiber, which is then braided into packing after impregnation in PTFE dispersion. This high carbon packing has good heat conduction and low corrosion rate,and the price is relatively lower, so it’s generally used in dynamic sealing in the presence of weak acid or alkaline media, or media that contains few solid particle grains.

.jpg)

.jpg)