Product Categories

Black PTFE Teflon Tubing / PTFE Teflon Material For Heat Exchange

Product number:kaxite-t004

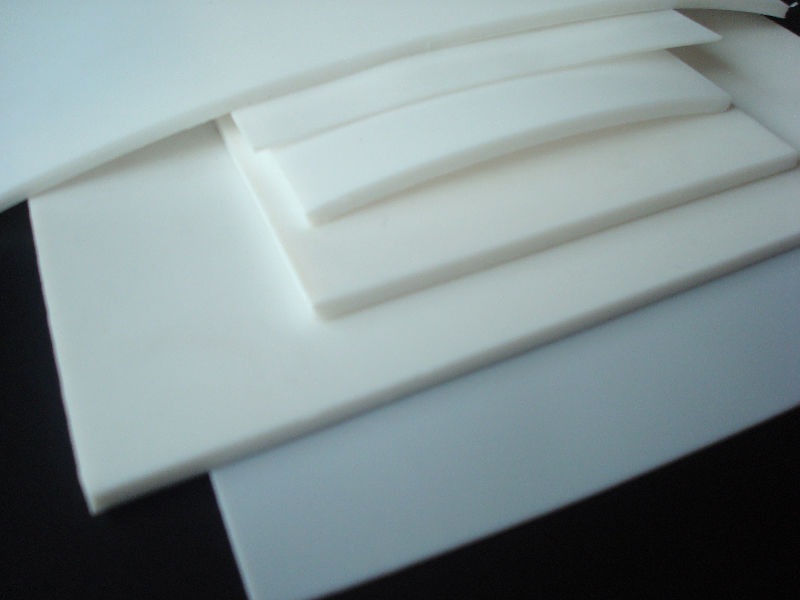

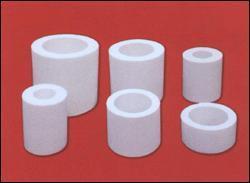

Quick Overview: Filled teflon PTFE tube is manufactured by technics of molding method in the diameter from 0.5mm to 1800mm with PTFE granular resin. As PTFE has a very low co-efficient of friction, so the surface of filled teflon PTFE tube has similar friction levels to ice. Filled teflon PTFE tube can work at -180°C ~+260°C and is the best electrical insulator of all known plastics.

Send Inquiry

PDF DownLoad

Product Description

Detailed Product Description

| Apparent Density: | 2.10 - 2.30 G/cm³ | Applications: | Heat Exchanger |

|---|---|---|---|

| Color: | Red, Yellow, Black | Diameters: | 0.5 - 1800mm |

| Product Name: | PTFE Teflon Tube | Temp: | -180°C - 260°C |

Related Products

Extruded PTFE Teflon Tube

White Filled PTFE Teflon Tube

Extruded PTFE Teflon Tube / Teflon Tubing For Wire , 0.5mm - 250mm

Natural White PTFE Teflon Tubing / PTFE Teflon Hose For Automobile, 2.14 - 2.20g/cm³

White Filled PTFE Teflon Tube / Tubing 2.10g/cm³ For Cable Jacket

Black PTFE Teflon Tubing / PTFE Teflon Material For Heat Exchange

White PTFE Teflon Tube Polytetrafluoroethylene PTFE For Industry

White PTFE Teflon Tubing / Teflon Tubing For Wire Braided Hose , No Impurities

Silver PTFE Teflon Tube , PTFE Teflon Pipe Wrapped Stainless Steel Wire

Non-Contaminating Black Carbon Fiber Filled Ptfe Tube , High Temperature Resistance

Protecting PTFE Teflon Tube , Teflon PTFE Heat Shrink Tubing

Protecting PTFE Teflon Tube , Teflon PTFE Heat Shrink Tubing

Natural White Extruded Polytetrafluoroethylene Tube For Wire , 0.5mm-250mm

Anti-Corrosion PTFE Teflon Tube / PTFE Lined Pipe Power Plant

Non-Stick PTFE ring , 2.30 g/cm³ PTFE O-Rings For Pipe Fittings -180 °C - 260 °C

Formable PTFE Teflon Tube Wire Braided , PTFE Teflon Braided Hose

White PTFE tube , 2.10g/cm³ PTFE Soft Joint / PTFE Material For Metal Tube

Graphite Filled PTFE Teflon Tube Hydrochloric Acid Heat Exchanger

Natural White Pure Extruded PTFE Teflon Tube For Wire And Cable Jacket

High Temperature Resistance PTFE Teflon Tubing With Long Durability

Natural White PTFE Teflon Tube High Chemical Resistance Wire Use